5 Steps to Make Moonshine Mash at Home

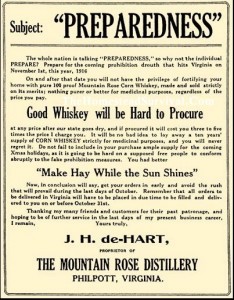

In the serene quiet of the countryside or in the cozy confines of your own kitchen, crafting moonshine at home is both an art and a science, rooted deep in American culture and history. The first step towards creating that smooth, potent libation is preparing the perfect moonshine mash. Here, we guide you through five crucial steps to create a mash that serves as the foundation of your homemade spirits. Let’s delve into the enchanting world of moonshine!

Step 1: Gather Your Ingredients

To begin, you’ll need:

- 5-10 pounds of cornmeal or grains (preferably cracked corn for better fermentation)

- Water (You’ll need about 5 gallons to mix with the grains)

- Sugar (usually between 5 to 10 pounds, depending on the desired alcohol content)

- Yeast suitable for alcohol production (Turbo Yeast is a popular choice)

- Optional additives like barley or malt for improved flavors

Step 2: Prepare the Mash

The key to a good mash is the correct proportion of ingredients:

- Mix 5 gallons of water with your grains in a large pot.

- Heat the mixture to about 160-180°F. This temperature helps convert starches to sugars without cooking the grains too much. Stir regularly to avoid burning.

- Once the mixture is at the right temperature, reduce heat, stir in the sugar until it dissolves completely. For sweetness and fermentation, it’s vital that the sugar is fully dissolved.

- Allow the mash to cool to below 90°F for yeast addition.

Step 3: Fermentation Process

Fermentation is where the magic happens:

- Once your mash has cooled, stir in the yeast. Ensure even distribution to avoid clumping.

- Cover your fermenter with a lid or cheesecloth to keep out contaminants while allowing for CO2 release.

- Place in a cool, dark place to ferment for 7 to 10 days. The optimal temperature for fermentation is around 65-75°F. Monitor the activity (bubbling) to know if fermentation is active.

Step 4: Monitoring and Troubleshooting

During this stage, be vigilant for:

- Stuck Fermentation: If fermentation slows or stops prematurely, check the temperature, add more yeast, or aerate the mash gently.

- Off Flavors: If you notice unusual smells, it might indicate contamination. Consider a new batch if it’s not salvageable.

- Bubbling: Monitor the airlock or the surface of the mash for consistent bubbles, a sign of healthy fermentation.

🍸 Note: Patience is crucial in the fermentation process. Resist the urge to peek too often to avoid contaminating your brew.

Step 5: Checking Mash Readiness

How do you know your mash is ready?

- Use a hydrometer to measure the specific gravity. Compare the readings to determine when the fermentation has converted most sugars to alcohol.

- The taste should be sour and alcoholic; the smell should remind you of beer or bread.

- Finally, if you’re ready to distill, transfer the mash carefully to avoid disturbing the sediment at the bottom.

🍯 Note: Mash quality significantly affects your final moonshine. Clean equipment and precise measurements are key.

In crafting moonshine at home, the initial mash preparation is your ticket to a high-quality spirit. Each step, from selecting the right ingredients to monitoring fermentation, needs attention to detail to ensure a successful batch. The journey through making moonshine is filled with lessons on patience, precision, and the subtle alchemy of fermentation. It's not just about the end product; it's about the love and care poured into every aspect of the process.

What’s the best corn type for moonshine mash?

+

Cracked or flaked corn is typically the best choice. It’s pre-processed to expose more of the starches, allowing for better sugar conversion during fermentation.

How can I tell if my mash has gone bad?

+

Watch for sour or rotten smells, mold growth, or any off-taste. If fermentation stops unexpectedly, it could be due to contamination or issues with the yeast.

Can I use regular baking yeast instead of alcohol yeast?

+

Yes, you can, but be aware that bread yeast might not survive the high alcohol environment of distilling, potentially leading to incomplete fermentation or undesired flavors.