5 Essential Tips for Face Milling Success

Face milling is a machining process that's crucial for achieving flat surfaces with precision and efficiency. Whether you're working in automotive manufacturing, aerospace engineering, or any other industry requiring accurate machining, understanding how to maximize your face milling operation can lead to improved quality, reduced cost, and faster production times.

Choose the Right Milling Cutter

The first step in ensuring a successful face milling operation is to select an appropriate milling cutter. Several key factors should influence your choice:

- Diameter of the Cutter: A larger cutter diameter can cover more surface area per pass but might be less agile in tight spaces.

- Number of Inserts: More inserts can increase productivity by reducing the number of passes needed, but this also depends on the material being milled.

- Material: Carbide inserts are typical for general milling, while coatings like TiAlN can offer benefits when milling high-temperature alloys or hard materials.

- Lead Angle: A positive lead angle leads to smoother cutting action and better chip control.

Setup the Machine and Workpiece Correctly

Correct setup is vital for face milling:

- Ensure Rigidity: Both the workpiece and the machine setup must be rigid to prevent chatter and vibrations, which can affect surface finish.

- Clamping: Use appropriate clamps to hold your workpiece securely. Clamping should be done in a way that minimizes deflection during cutting.

- Alignment: The spindle axis should be perpendicular to the workpiece to achieve a flat surface. Any misalignment will result in uneven milling.

💡 Note: Always check for backlash in the machine setup as this can cause inaccuracies in milling.

Optimize Cutting Parameters

Optimizing the cutting parameters is crucial:

- Speed and Feed: Balance between speed (rpm) and feed rate (mm/min) for the best results. Too high of a speed can lead to overheating, while a low feed might cause rubbing rather than cutting.

- Depth of Cut: The axial depth of cut (ap) determines the amount of material removed per pass. Deep cuts can reduce the number of passes but increase power requirements.

- Coolant: Use adequate coolant or lubrication for heat dissipation and to keep chips out of the way.

| Material | Speed (m/min) | Feed (mm/tooth) | Depth of Cut (mm) |

|---|---|---|---|

| Steel (S355) | 150-250 | 0.1-0.25 | 2-10 |

| Aluminum | 300-1000 | 0.1-0.35 | 3-15 |

| Cast Iron | 100-200 | 0.1-0.2 | 2-10 |

Manage Chips Effectively

Chips can cause significant issues if not managed correctly:

- Use Appropriate Inserts: Inserts with specific geometries can improve chip evacuation.

- Cutting Fluid: Ensure cutting fluid reaches the cutting zone to help clear chips.

- Chip Form: Different materials produce different chips; select milling strategies that manage these chip forms effectively.

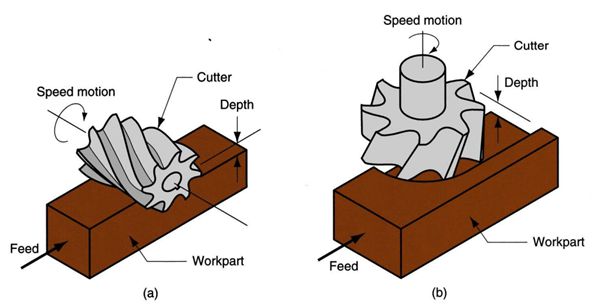

Understand and Utilize Different Milling Strategies

Face milling can be approached in various ways:

- Conventional vs. Climb Milling: Climb milling is often preferred for better surface finish and tool life, reducing the risk of work hardening the material.

- Half-Side Milling: Useful for high productivity when both sides of the cutter can be used simultaneously.

- Fine Face Milling: For applications requiring very high accuracy, smaller tools with finer feeds are used.

⚠️ Note: Always consider the workpiece material when selecting a milling strategy. For instance, climb milling is less effective on workpieces with hardened surfaces.

In closing, the art of face milling is both a science and a craft, requiring an understanding of tools, materials, machines, and processes. By following these tips, machinists can significantly enhance their face milling operations, leading to better results in terms of quality, efficiency, and cost-effectiveness. The right cutter, optimal setup, cutting parameters, effective chip management, and appropriate milling strategies together form the backbone of successful face milling. Remember, continuous improvement through experimentation and adaptation to each unique job's demands is key.

What is the difference between face milling and peripheral milling?

+

Face milling involves cutting a wide area with a face mill cutter, primarily to produce a flat surface. Peripheral milling, on the other hand, is used for cutting along the edges or creating slots with a side mill or end mill.

Why is it important to manage chips in milling operations?

+

Effective chip management prevents tool breakage, reduces the chance of surface damage, and improves overall productivity by keeping the cutting area clear.

How can I tell if my cutter is appropriate for the job?

+

Check the material of the workpiece, the desired surface finish, and the required cutting speed and feed rate. Your cutter should be suitable for these parameters in terms of insert material, geometry, and coating.

What are the signs of improper face milling setup?

+

Signs include chatter marks, excessive tool wear, poor surface finish, and inaccurate dimensions. These issues often arise from an unstable setup or incorrect cutting parameters.

Can I use the same strategy for different materials?

+

No, different materials require different strategies due to their unique properties. What works for aluminum might not be optimal for steel or cast iron, as each material affects tool life, surface finish, and cutting mechanics differently.