6 Easy Cone 6 Gray Glaze Recipes

Introduction to Cone 6 Gray Glaze

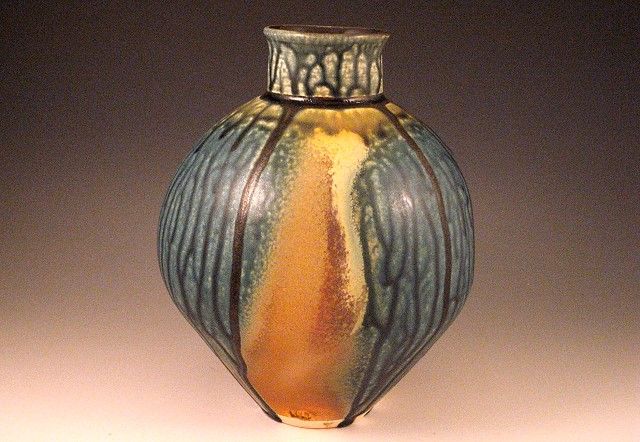

Gray glazes offer a wide range of beautiful, versatile finishes from cool, slate tones to warm, almost brownish hues. They are particularly popular in pottery for their ability to enhance texture and complement various forms of clay bodies. In this guide, we'll delve into six easy-to-make cone 6 gray glaze recipes that are perfect for potters at any skill level, providing both functionality and aesthetic appeal.

What is Cone 6?

Cone 6 refers to the temperature at which a pyrometric cone bends or melts, signaling that the kiln has reached the designated firing temperature. For potters, Cone 6 is widely used because it's the midpoint between low and high fire, offering durability with more ease in terms of firing time and energy costs. Here's what you need to know about firing at cone 6:

- Firing Range: Cone 6 typically fires at about 2232°F (1222°C).

- Clay Types: Suitable for a variety of mid-range clays like porcelain, stoneware, and some earthenware.

- Glaze Properties: Glazes melt well, providing a good seal but might not be as glossy or as glass-like as high-fire glazes.

6 Easy Cone 6 Gray Glaze Recipes

Let's explore these six glaze recipes that will add unique shades of gray to your ceramic pieces:

1. Simple Gray Glaze

- EPK Kaolin: 32.0% - Silica: 24.0% - Whiting: 20.0% - Feldspar (Custer): 20.0% - Zinc Oxide: 4.0%

- Mix all ingredients thoroughly.

- Add water until you reach the desired consistency for glazing.

- Apply to bisqueware and fire to cone 6.

This simple recipe yields a consistent, elegant gray tone that complements many ceramic forms.

2. Smooth Smoke Glaze

- Nepheline Syenite: 38.5% - Silica: 26.0% - Whiting: 12.0% - Zinc Oxide: 6.0% - Iron Oxide (red): 1.0% - Bentonite: 2.0% - Borax: 2.0%

- Combine all ingredients, ensuring an even mix.

- Adjust water content for glazing.

- Fire at cone 6 for a smooth, smoky gray finish.

💡 Note: Adjust the iron oxide to change the color tone slightly.

3. Moonlit Gray Glaze

- Albany Slip Substitute (or Ravenscrag Slip): 60.0% - Silica: 18.0% - Barium Carbonate: 8.0% - Tin Oxide: 2.0% - Copper Carbonate: 1.0%

- Mix, sieve, and adjust the glaze consistency.

- Apply multiple layers for depth and intensity of color.

4. Ash Gray Glaze

- Wood Ash: 50.0% - Kaolin: 30.0% - Silica: 10.0% - Whiting: 10.0%

- Blend and prepare glaze to the right thickness.

- Great for showcasing the natural texture of the clay.

5. Textured Silver Ash Glaze

- Silica: 30.0% - Whiting: 20.0% - Ball Clay: 20.0% - Nepheline Syenite: 20.0% - Rutile: 5.0% - Zinc Oxide: 5.0%

- Mix ingredients, add water, and sieve.

- This glaze can be applied thickly for a textured look.

6. Dove Tail Glaze

- Kaolin: 30.0% - Wollastonite: 15.0% - Whiting: 15.0% - Silica: 20.0% - Tin Oxide: 3.0% - Copper Carbonate: 2.0% - Feldspar (Custer): 10.0%

- Prepare glaze mixture, ensuring a smooth application.

- Fires to a deep, rich gray with subtle blue undertones.

Application Tips and Notes

Applying glaze is both an art and a science. Here are some tips for achieving the best results:

- Cleanliness: Ensure bisqueware is clean to avoid flaws in the glaze surface.

- Application: Use different techniques like brushing, dipping, or spraying to achieve varied effects.

- Layering: Multiple layers can deepen the color and provide a more complex finish.

- Firing: Be consistent with your firing schedule for predictable results.

⚠️ Note: Over-application or too thick glaze layers can lead to cracking or running during firing.

In wrapping up our exploration of cone 6 gray glaze recipes, remember that each recipe provides a foundation. The final appearance can be influenced by factors like clay body, firing schedule, and even the thickness of the glaze application. Experimentation is key. Here are the key takeaways:

- Diverse Shades: From cool slate to warm, smoky grays, the options are nearly endless.

- Simplicity in Ingredients: Many recipes use commonly available materials.

- Versatility: Gray glazes work well with various clay bodies, enhancing both form and function.

Whether you’re looking for a consistent look or want to experiment with unique textures and finishes, these gray glazes can provide the perfect backdrop to showcase your pottery craftsmanship.

What are the key ingredients for achieving a gray glaze?

+

Key ingredients for gray glazes often include zinc oxide, silica, and iron oxide, which can be adjusted to achieve various shades of gray.

Can I mix different gray glazes to get a unique color?

+

Yes, mixing different gray glaze recipes can produce unique colors, but start with small batches to test the results.

What is the best way to apply multiple layers of glaze?

+

Allow each layer to dry slightly before adding the next, and apply evenly to avoid runs or drips during firing.

Does the color of gray change with different clay bodies?

+

Yes, the clay body’s color and composition can alter the appearance of the glaze. Test on the clay body you intend to use for the best results.

Is it possible to achieve a glossy gray glaze with these recipes?

+Most of these recipes produce a matte or satin finish, but adding more feldspar or introducing some boron can increase glossiness. However, experimentation is often necessary.